“Our goal is to increase our visibility, urge professionals to discover the fantastic qualities of bamboo as well as provide tools to conceptualize projects and integrate MOSO® Bamboo products into models. BIMobject offers the best-known and best-suited BIM platform to realize our goals.”

BIM builds coordination and collaboration

MOSO® Bamboo is the leading supplier of high-quality bamboo products in 50+ countries. With 25 years of experience in the relatively young bamboo industry, MOSO International is considered a global A-brand in bamboo because of its focus on product quality, innovation, and sustainability.

Candlewood Lake, Private Residence. Photographer: Rob Turner Studios. Product: Exterior Flooring MOSO® Bamboo X-treme®

But how does BIM fit into their business triad? And how can manufacturers benefit from the digital building process? Fanny Cariou explains:

“BIM ensures the coordination between the different professionals working on a project. It makes it possible to highlight the compatibility of materials and allow access to key information once the project is delivered. BIM will only continue to grow in the future.”

Products rooted in sustainable materials and manufacturing

For MOSO®, sustainability is more than corporate social responsibility or a fashion statement used to allure architects. It’s the very core of their business. The brand manufactures interior and exterior products from the giant bamboo species mōsō, which grows faster than any other plant in the world (4-5 year maturity).

The material’s properties make their products durable, fire resistant, and CO2 neutral. This makes it the ideal alternative to tropical wood and one of the most promising raw materials to build toward net-zero carbon emissions. In addition, MOSO®’s production facilities are ISO 9001, and ISO 14001 certified to ensure compliance with the strictest health, safety, and environmental regulations.

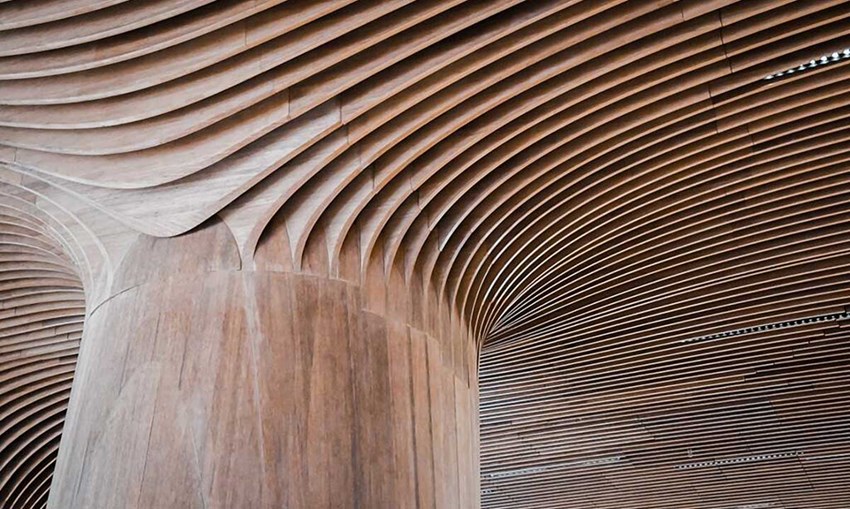

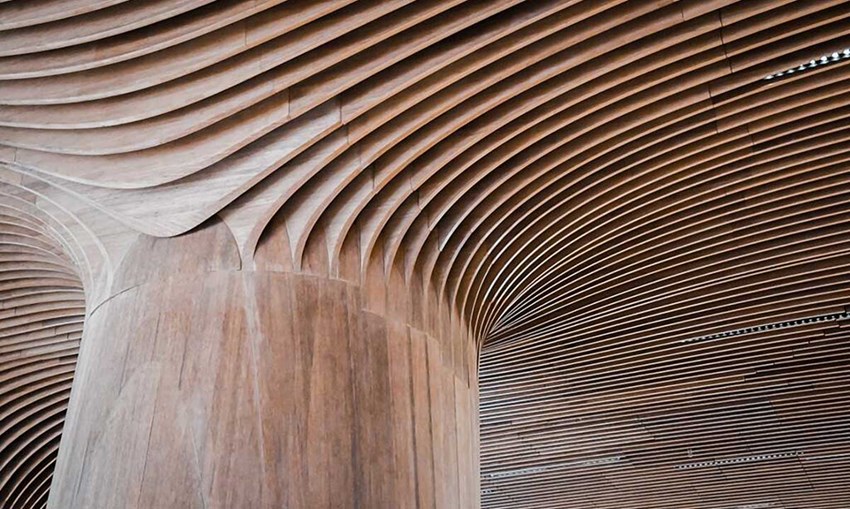

Jakarta Hotel. Photographer: Lior Teitler. Product: MOSO® Bamboo Elite

MOSO® Bamboo is a breath of fresh air in an industry (and world!) starved for sustainability. The harrowing truth is that buildings and construction are responsible for 39% of energy and process-related CO2 emissions and 36% of final energy use. But the needle is finally starting to move: governments, the market, and architects are joining forces to put pressure on sustainability.

Want to know what the new green demands mean for you? Get your hands on our new report: Why sustainability is key to getting specified.

Manufacturers need to get digital to gain visibility

With over 20 years of market experience, MOSO® Bamboo is known for not shying away from new innovations. Rather, they embrace all relationship-enhancing digital advancements with open arms:

“We have always opted for online visibility. We share a lot of content about our raw material, sustainability, and inspiration for projects through our website and social networks”, states Fanny Cariou and continues:

“Our objective is to get closer to designers and architects and improve their general user experience. In 2020, we decided to expand our online positioning and increase visibility by offering new content through BIMobject.”

Photo by AndreVisual

MOSO® Bamboo is a digital pioneer in the rather analog building industry. But as we’ve uncovered in how manufacturers can navigate the new digital landscape, things are starting to change: architects and engineers now favor digital modes of product exploration (59%) over the more traditional trade show (9%).

But what does this mean for you, as a manufacturer? Well, you’ll need to follow MOSO®’s footsteps and get digital to reach architects and meet their needs.

How to drive sustainability through digitization

Digitization and digital building processes offer additional benefits beyond greater measurability and KPIs. As Fanny stated in the earlier parts of this interview: “[BIM] makes it possible to highlight the compatibility of materials and allow access to key information once the project is delivered”.

By creating BIM content (information-rich digital product twins), manufacturers play a key role in facilitating sustainable design. But how does it work? For every BIM project, designers must create a 3D representation of the building using digital building components; BIM files. This replica model allows designers to generate simulations that make it possible to:

- Reduce waste by preventing, detecting, and correcting errors and clashes

- Analyze the energy consumption of the building

- Calculate and mitigate the project’s carbon footprint

- Save time, reduce costs and save materials by improving the flow of information and project coordination.

However, sustainable and forward-thinking designers are dependent on manufacturers creating BIM files that they can easily put into their designs. So, by creating BIM files and getting on the BIMobject digital marketplace, MOSO® Bamboo doubled its commitment to sustainability.

Want to tap into the same business perks as MOSO? Find out how the BIMobject marketplace can help you get into the green.

Ana Martinez

Customer Marketing Manager