BIM, Building Information Modeling, is transforming the construction industry. From improved collaboration to increased efficiency, the benefits of BIM are undeniable. But what does the future hold in store? And what emerging trends and technologies should manufacturers be aware of? Let's take a closer look at some of the latest developments in the world of BIM.

BIM and beyond: emerging trends and technologies

Emerging trends are happening on the daily, and it can be challenging to narrow it down to just a few. So, we have gathered 9 important BIM-related trends that have the potential to transform the way you work, market your brand, and get your products specified.

BIM trend 1: BIM mandates

Can manufacturers neglect to comply with BIM mandates in this day and age? The answer is no! BIM mandates are becoming a requirement rather than an option in the construction industry due to its benefits, such as improved project outcomes and increased efficiency.

This trend is not only driven by technological advancements but also by political strives to improve a nation's competitiveness, productivity as well as social and environmental welfare. Manufacturers can gain a strategic advantage by complying with BIM mandates and creating BIM content to improve their product offering and better meet customer needs. To remain competitive in the market, it's important for manufacturers to stay informed on the latest BIM requirements.

Want to know if BIM is a requirement in your market? Get your hands on our full guide to BIM mandates now.

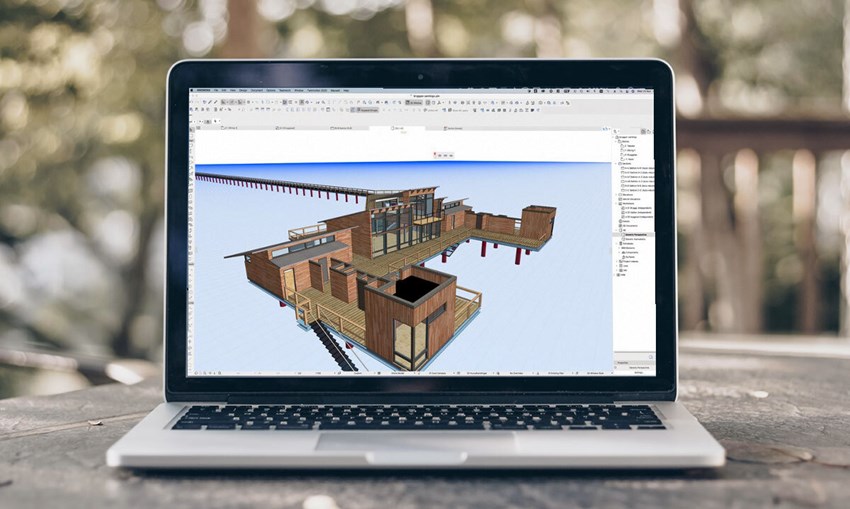

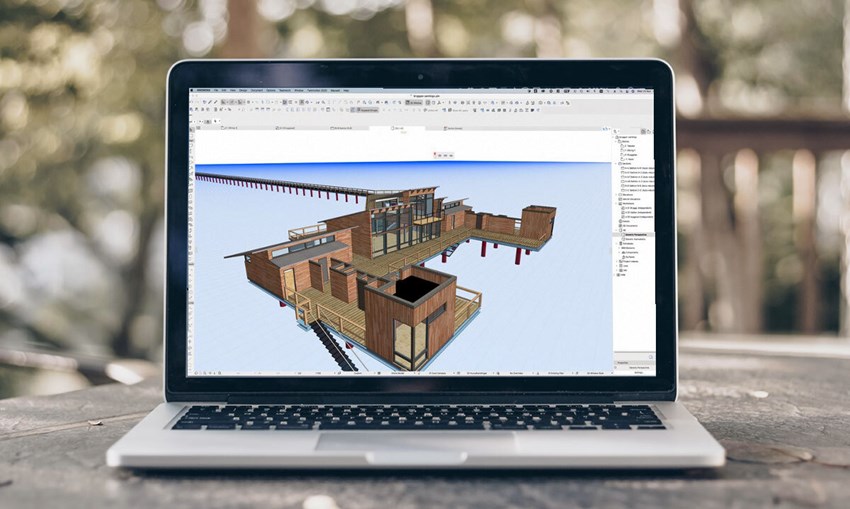

BIM trend 2: Adoption of BIM

Now you may be wondering, how does adoption impact manufacturers? Well, here’s the thing: BIM has become crucial as more private clients, companies and governmental entities recognize its value. According to USP’s Architectural Barometer Q2 2021 report, 44% of European Architects used BIM in 2021. That number’s expected to increase to 61% by 2025. “But what’s the fuel driving the massive increase in adoption? According to the 3,000 respondents in our February survey 2023 Architects, Engineers and Construction (AEC) on bimobject.com, the main motivators are to:

- Improve project quality: 28%

- Save time on the project: 22%

- Detect clashes, limit errors and omissions: 12%

- Gain a competitive advantage: 8%

- Increase profitability: 8%

- Win new business opportunities: 8%

- Adapt to regulation or law: 4%

- Respond to a request/call for tenders: 4%

- Other: 6%

Architects, interior designers and engineers are adapting their practices to incorporate BIM technology into their work. To accurately assess the environmental impact of their designs, these professionals rely on BIM objects provided by manufacturers as well as LCAs and EPDs. Therefore, the adoption of BIM is essential for manufacturers to remain competitive and meet the growing demand for BIM objects in construction projects.

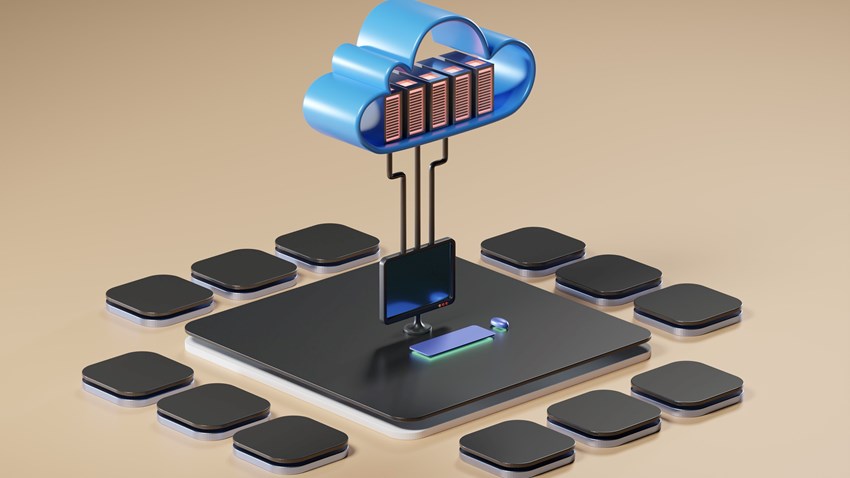

BIM trend 3: Cloud-based technology

Cloud-based BIM offers many benefits, including increased collaboration, accessibility, and real-time updates. Its main benefit is information management in which BIM objects play a massive role. With this technology, stakeholders involved in building projects can access and update BIM models from anywhere in the world, making it easier to collaborate on projects and work together seamlessly.

Manufacturers can take advantage of this trend by ensuring that their products are available on cloud-based BIM platforms, making it easier for stakeholders to integrate their products into BIM models. Cloud-based BIM also offers real-time updates, which can help teams stay on top of project changes and progress. With on-premises software, stakeholders may need to wait for updates or work with outdated information, which can cause delays and mistakes.

Cloud-based BIM, on the other hand, allows stakeholders to access the latest project information and collaborate in real-time. This trend is likely to continue, as the use of cloud-based technology becomes more widespread across industries. As more stakeholders embrace cloud-based BIM, we can expect to see even greater collaboration and accessibility, which will transform the construction industry.

BIM trend 4: The rise of digital twins

With the rise of digital twins, the construction industry is entering a new dimension of design and simulation. Digital twins are like doppelgängers of physical assets such as buildings or machinery, which allows stakeholders to see and analyze how their structures perform in different scenarios. By providing real-time data, digital twins enable better decision-making, optimize performance, and can even predict maintenance needs before they arise.

Digital twins have the ability to accurately simulate and predict the operational and behavioral aspects of a product based on real-world conditions. This enables manufacturers to make informed decisions about maintenance and support needs, optimizing product performance.

This reduces waste and rework, speeds up the design process, and improves the overall quality of the end product. One of its major perks is identifying potential bottlenecks before they occur.

Discover the critical decisions made at COP26 and their implications, including the essential role of digital twins.

BIM trend 5: BIM and prefabrication: A match made in heaven

If you're a manufacturer, you've probably heard about the growing trend of prefabrication. BIM and prefabrication are like two peas in a pod. Prefabrication is the process of building components of a building off-site and then assembling them on-site. BIM plays a critical role in this process by allowing manufacturers to create digital models of their components that can be easily integrated into the overall building model.

The use of BIM in prefabrication has many benefits for manufacturers, including increased efficiency, accuracy, and improved collaboration with other stakeholders. This allows for faster and more efficient assembly of components on-site. When manufacturers combine prefabrication with BIM, they can create components that fit seamlessly into the building model.

If you already downloaded our BIM mandates ebook you would know prefab is particularly popular in the Netherlands, and for a good reason! The Dutch have perfected the art of prefabrication due to its widespread use, resulting in faster and more effective construction processes.

BIM trend 6: Automation and BIM

Automation is another emerging trend that is transforming the world of BIM. Essentially, automation in construction is using digital processes, applications and robots to achieve tasks with minimal human input. Automation has many perks, one of them being more cost-effective in construction but it also decreases safety hazards.

By automating the process of generating BIM models, manufacturers can collaborate more effectively with architects, engineers, and other stakeholders in the construction process.

Automation in BIM can help the manufacturing process. Automation technologies such as robotics, sensors and AI can help manufacturers streamline production and improve product quality. These processes can also result in more flexibility and adaptability to changing product requirements, allowing manufacturers to better meet the needs of construction professionals using BIM.

BIM trend 7: The internet of things (IoT)

BIM is all about building better, faster, and greener. With the help of IoT and sensors, stakeholders can gain valuable insights into how their building projects are operating. IoT in construction can be used to monitor and control building systems, automate maintenance and repair tasks to enhance work safety.

By incorporating IoT sensors, manufacturers can gather real-time data on the performance and maintenance needs of their products. This data can be used to improve product design, optimize performance, and predict conservation needs, which can help manufacturers provide better service to their clients.

IoT data can be integrated with BIM software to provide construction professionals with more accurate and detailed information on the performance of building systems including HVAC, lighting and other equipment. IoT can allow manufacturers to better understand the needs of construction professionals and end-users enabling them to create better products that meet the competitive needs of their customers.

BIM trend 8: Artificial intelligence

BIM trend 8: Artificial intelligence

With its promising benefits, the integration of artificial intelligence (AI) is transforming the construction industry and manufacturers are one of the key stakeholders that can be impacted by this trend. By using AI algorithms, manufacturers can analyze project data and gain insights into the performance of their products and make data-driven decisions on how to improve them.

In the construction industry, AI can help monitor performance and detect issues before they occur. It can also help improve quality control and can be used to analyze large amounts of data and identify patterns that can help optimize the design and construction process.

For example, AI can be used to examine data to further predict potential delays in construction schedules. AI-powered tools such as chatbots can also help customers, and other stakeholders get quick answers to their questions, improving overall customer satisfaction and reducing the workload on customer support teams.

If that is not enough, AI can also be great at analyzing data on materials and building components to identify areas for improvement in terms of cost, efficiency, and sustainability. Ricardo Piazzai talks more about understanding the need of sustainable design and BIM and the importance of collaborating with manufacturers who share the same vision.

BIM trend 9: Virtual augmented reality

BIM processes are being impacted by the emergence of augmented reality technologies. These are becoming increasingly integrated into the construction industry, offering new ways to visualize and interact with BIM data. These technologies can be used to picture and simulate construction projects, allowing stakeholders to get a better understanding of them before they are built.

Virtual augmented reality also enables faster and easier examination of large-scale 3D models, providing stakeholders a comprehensive and clear image of the design and development process. In the future, virtual augmented reality is expected to enhance the BIM modeling process by providing a detailed look at every step of the design process.

This can be an impressive way to showcase products and designs to customers, allowing them to get a better sense of what they'll be getting before they commit to a purchase. Virtual augmented reality can also help visualize product designs and improve collaboration with project teams. It can help reduce errors and improve overall project quality by potentially identifying and addressing issues before construction begins.

In a recent interview, Negar Daneshpour, lead architect at Tyréns, touches upon the real-life use of virtual reality in construction today. A case scenario where people were able to engage in the use VR glasses to experience a 3D model.

BIM-Possible Future

The future of BIM is full of possibilities. Manufacturers have a wealth of new tools and technologies at their disposal. But to take advantage of these opportunities, manufacturers must be willing to invest in the necessary training and tools, and stay up-to-date with the latest developments in the field.

BIM objects are becoming increasingly common in the construction industry, and it's essential for manufacturers to prepare for these changes by ensuring that their products are BIM-compatible. By embracing these technologies, manufacturers can unlock new opportunities for growth, efficiency, and innovation. It's time to start exploring the possibilities of BIM. The future is exciting, and the possibilities are endless.

Want to start your BIM journey but not sure how?

Digitizing your products is the first step in entering the world of digital construction. With more than 14 years of experience, our BIM experts will be happy to advise and assist you throughout the process.

> Schedule your demo now <

Denisse Luna

Content Marketer

BIM trend 8: Artificial intelligence

BIM trend 8: Artificial intelligence